- To achieve carbon neutrality via BEV and e-POWER twin-pillar strategy

- Developed breakthrough technologies to achieve ‘EV-ness’ in e-POWER

- Unique combination of EV performance with class-leading fuel efficiency

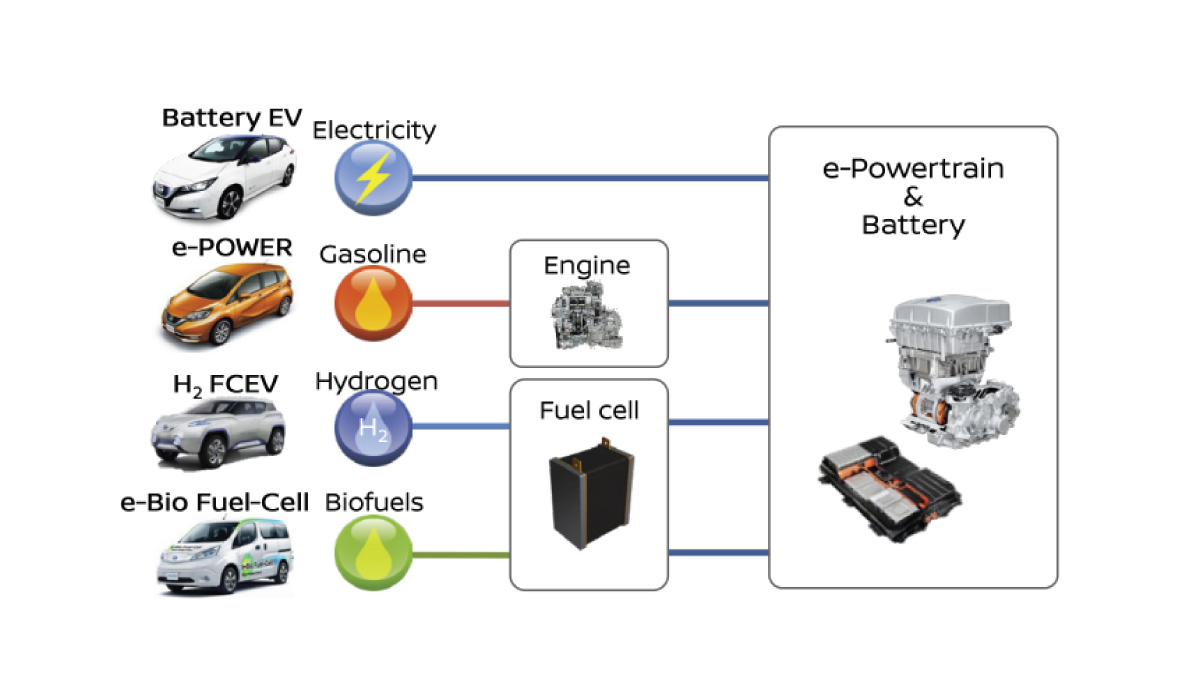

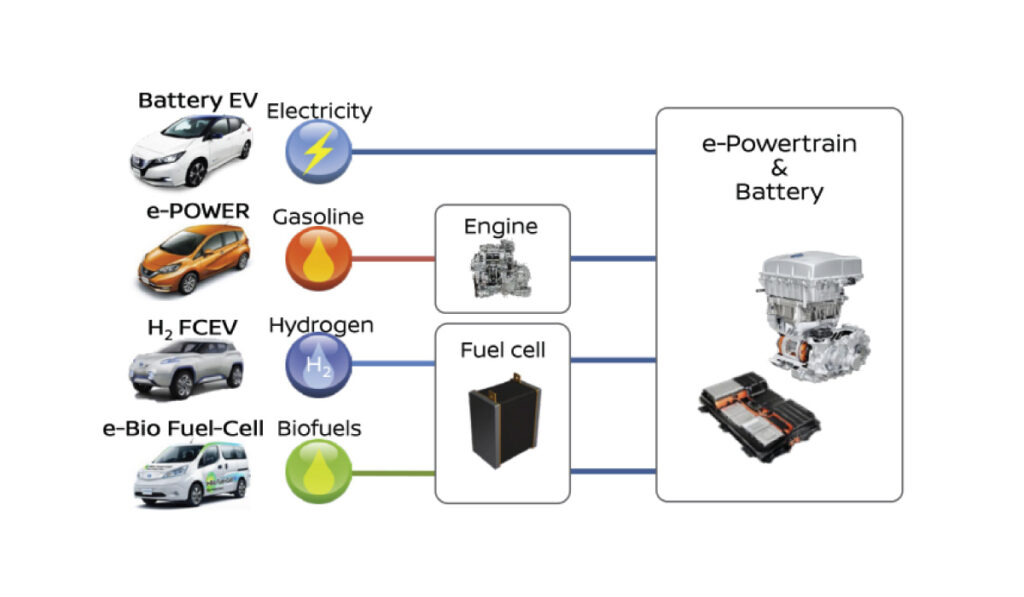

Kuala Lumpur, 28 August 2024 – When Nissan commenced its technical development strategy in 2005, one of the key objectives was to achieve carbon neutrality in the long term through a gradual adoption of battery electric vehicles (BEV) as well as electric motor-driven vehicles powered by energy sources such as hydrogen fuel cell, e-bio fuel cell and ICE-based power-generating systems.

Nissan eventually launched the world’s first mass-produced BEV in the all-electric LEAF in 2010 and to offer electric motor-driven e-POWER models as one of the twin pillars of its electrification strategy. As a new entrant competing in the crowded Japanese hybrid market in the mid-2010s, e-POWER promised superior fuel efficiency and EV-like driving characteristics which the Nissan Note e-POWER duly delivered in 2016, becoming no.1 best-seller in the Japanese domestic market.

Harnessing ‘EV-ness’ in e-POWER

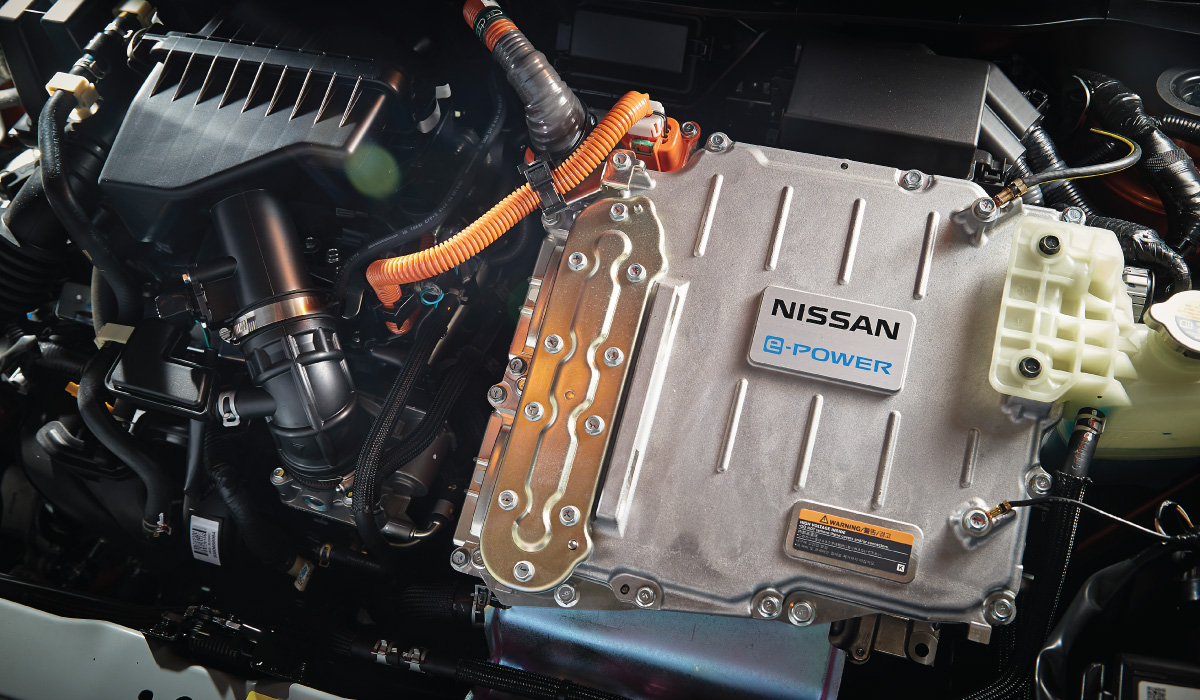

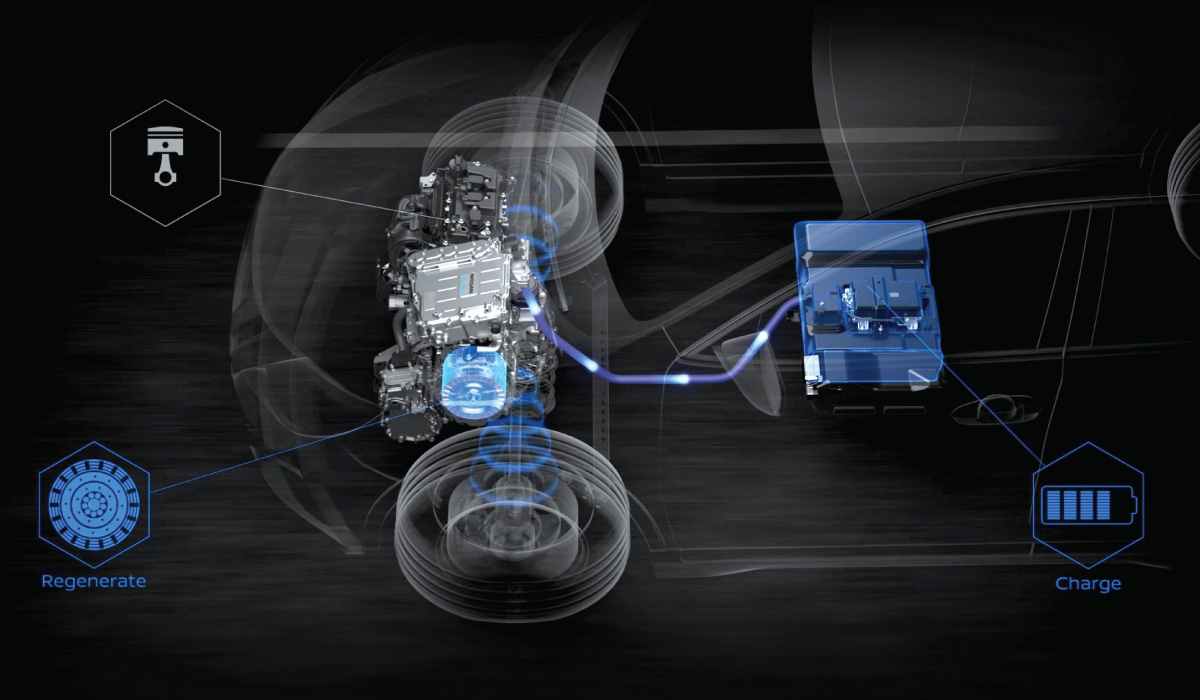

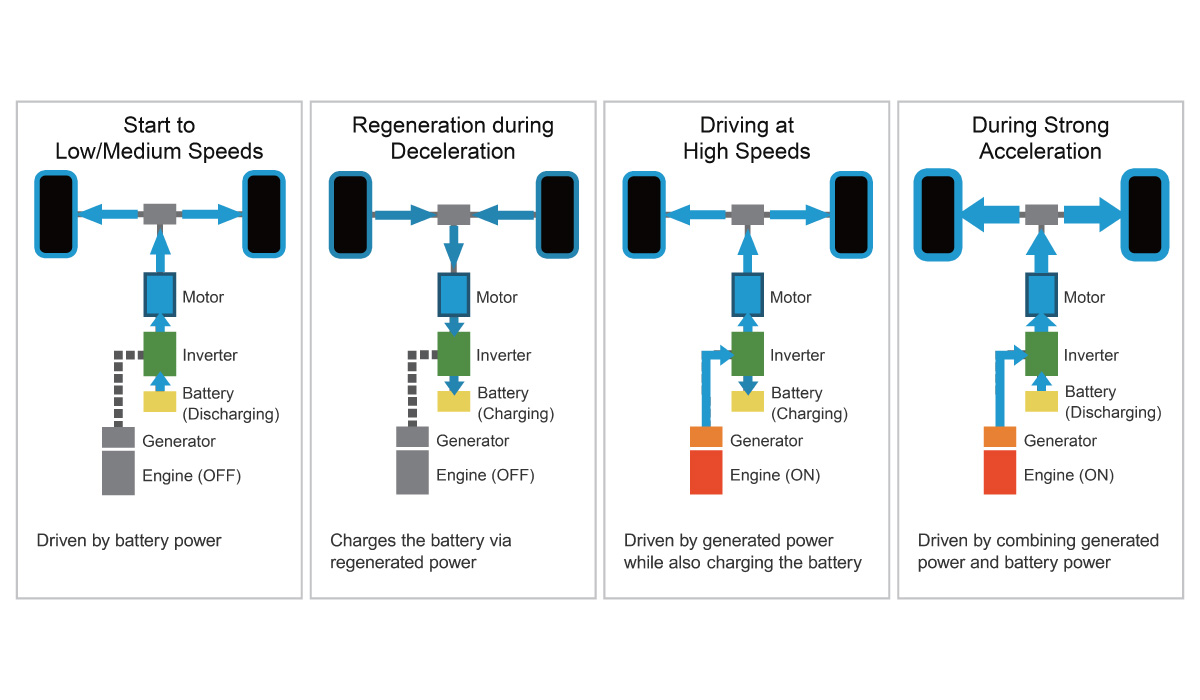

Unlike conventional parallel hybrids which are predominantly powered by a petrol engine with limited electrical assistance, the wheels of an e-POWER vehicle are 100% driven by an electric motor. It utilises a combustion engine to power a generator which charge up its on-board Lithium-ion battery pack.

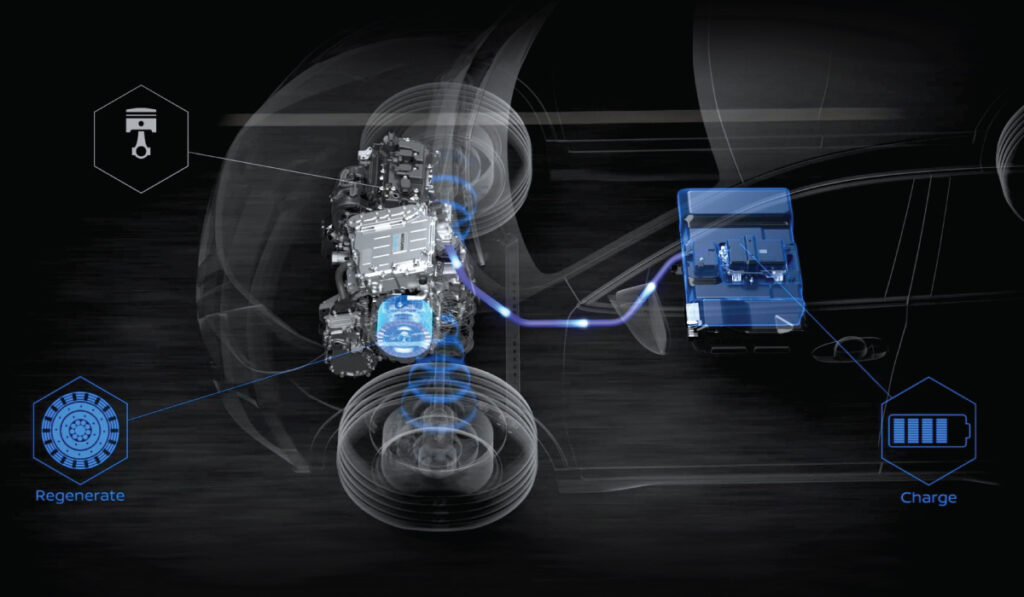

Nissan engineers adapted key components of the all-electric LEAF such as its inverter (the brains of an EV) and advanced control systems to harness the essence of electric drive – instant torque response and quiet, smooth performance – and applied them to e-POWER, giving it the characteristic ‘EV-ness’ which drivers appreciate.

Unlike similar forms of hybrids where noise, vibration and harshness (NVH) of the generator are typically not well isolated, an e-POWER’s internal combustion engine is calibrated to be discreet and only operates on a fixed-point basis where the engine is at its most efficient range to generate electricity. Additionally, the engine would come on in phases when the ambient noise is high (e.g. cruising at highway) so that the operation is masked acoustically.

Intelligent system operation and integration

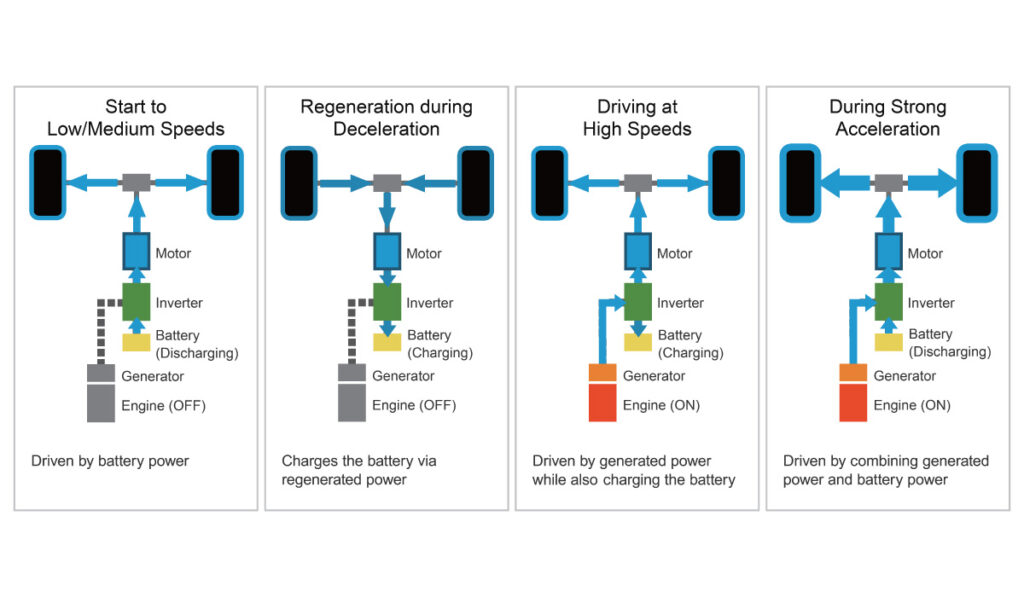

When maximum performance is required, the engine in an e-POWER system is capable of supplying power directly to the motor while charging the battery at the same time to ensure sustained performance, this innovation by Nissan is unique to e-POWER and not found on traditional hybrid systems, furthermore, it negates the need for much larger high-capacity battery packs which adversely impacts weight and packaging.

Instead, a compact Lithium-ion battery with high power density and output was developed exclusively for e-POWER, the advantage of which is seen in the kerb weight of Nissan e-POWER models which are equivalent to ICE-powered models, but with superior weight distribution. As e-POWER is 100% motor-driven (via a gear reducer), a traditional transmission is not required and this not only reduces weight but also long-term maintenance costs.

e-POWER offers the best of both worlds

Against a backdrop dominated by BEVs, it’s easy to overlook Nissan’s e-POWER as another hybrid system centred around an internal combustion engine. Yet, e-POWER is the ideal step-up for car buyers who seeks the performance of a BEV and the fuel efficiency of a frugal hybrid.

The Nissan e-POWER drive system offers all the thrills and refinement of an EV through its 100% electric motor drive, but without the major drawback of range anxiety as it does not require external charging, which in turn eliminates the hassles associated with EV ownership, such as long charging time, lack of chargers and malfunctioning chargers

Innovations in engine and battery technologies, along with proprietary control systems and intelligent features such as e-Pedal Step energy regeneration gives e-POWER class-leading hybrid efficiency compared to ICE-powered vehicles. For many markets that are not ready to adopt BEVs en masse, e-POWER is the unique solution that comes without compromises.

About e-POWER

The e-POWER drive system is a technology unique to Nissan, it utilises a petrol engine to charge a Lithium-ion battery pack which then powers an electric motor to drive the wheels. It offers instant torque and responsive performance like an EV, but without range anxiety and without the need to plug in and charge. Compared to a traditional combustion engine, the e-POWER system has lower tailpipe emissions and running costs, it even utilises regenerative braking to reclaim energy and replenish the battery pack. Nissan plans to launch an all-new e-POWER model in Malaysia in Q4 2024.

Stay tune to discover more about the innovation behind e-POWER.

###

About Edaran Tan Chong Motor Sdn Bhd

Edaran Tan Chong Motor Sdn. Bhd, a wholly-owned subsidiary of Tan Chong Motor Holdings Berhad (TCMH), is the sales and marketing arm of Nissan vehicles in Malaysia. In 1957, Tan Chong Motors was appointed the franchise holder of Nissan/Datsun vehicles in Malaysia and Nissan/Datsun became the best-selling brand in the country in 1970. TCMH was listed on the Bursa Malaysia Securities Berhad in 1974. The group is principally involved in the assembly and distribution of automobiles. To complement TCMH’s auto business, TCMH provides a wide range of services such as vehicle after sales, hire purchase financing, leasing, and insurance.

For media enquiries, please contact:

Tiffany Tan

T: 03-2788 3157

E: tiffany@tanchonggroup.com

Chuah Joo Ee

T: 03-2788 3160

E: jooee.chuah@tanchonggroup.com